So you want to save money by buying our unfinished or custom-finished kitchen cabinets. Can you also save money on the installation, which often doubles your overall costs? There are many projects and do-it-yourself (DIY) jobs in the average home that do not require bringing in a professional. Who doesn’t like saving money when we can successfully accomplish a project on our own, on our own schedule?

However, there are home projects that require the services of a trained, experienced, and licensed contractor. A project in the hands of someone that is not qualified could end up costing much more than hiring the correct professional in the first place. You can almost always save time (and possibly money) when the job is done correctly the first time. And you are better off handling dangerous or risky conditions with an expert.

This rule of thumb is a good basic starting point: Do you have mechanical, electrical, or plumbing issues in your project? You might be skilled and knowledgeable enough to tackle one or more of these issues, and perhaps bring in a professional for the other items.

I just need kitchen cabinets, do I need a contractor?

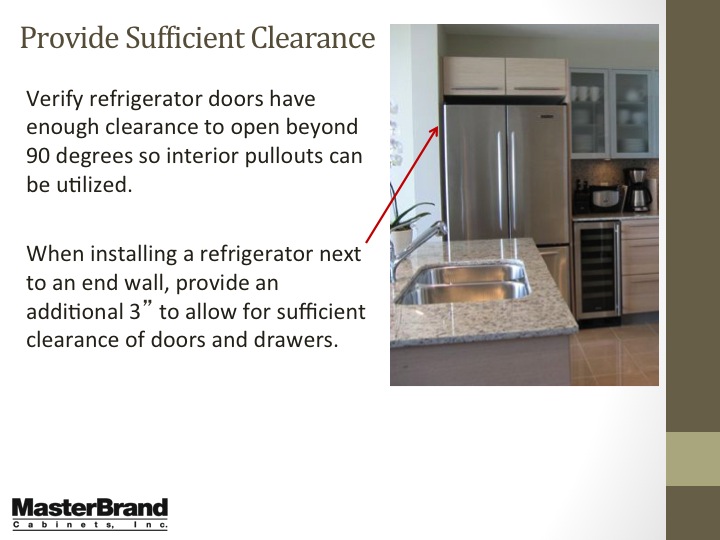

If you are only removing and replacing your existing cabinets, you might not need a contractor. This is often the case with very simple kitchen renovations. For example, if you can disconnect and reconnect the plumbing under your sink, your electrical outlets are staying and you’re not adding any new ones, you’re not changing your type of range, not adding a dishwasher, then you might not need a contractor.

Why would my renovation affect anything mechanical, electrical, or involve my plumbing?

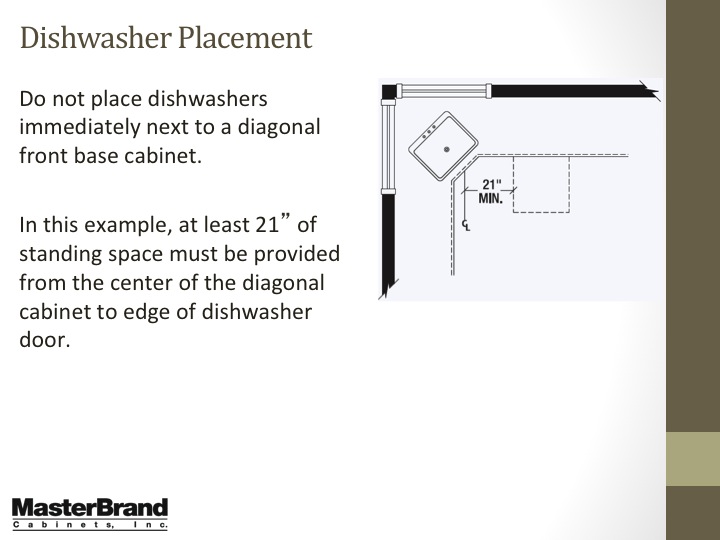

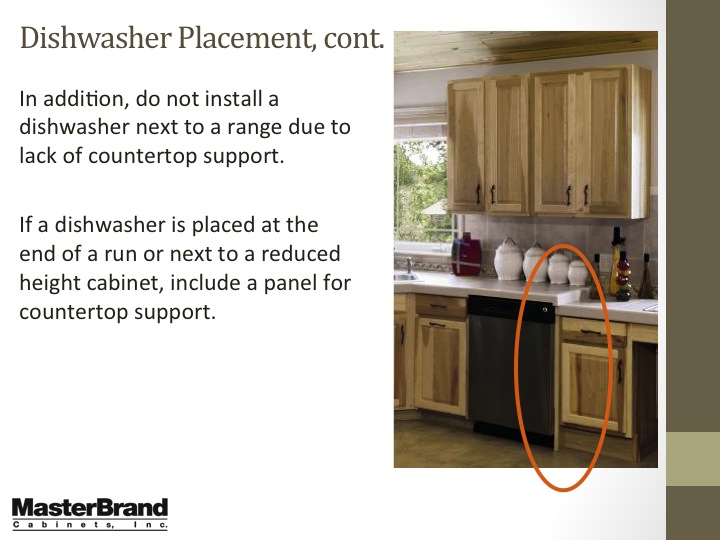

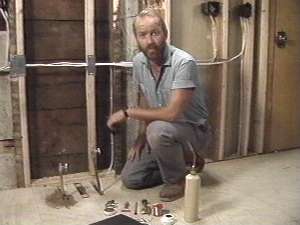

Are you considering taking a wall down in your kitchen to create more space? Does your kitchen design include a new island that will need an electrical outlet? Are any of your appliance locations changing? At the very least, your plumbing will need disconnecting and reconnecting. While some of these items are usually straightforward tasks, there can certainly be more involved things that come up.

If mechanical, electrical, or plumbing issues are involved, the rule of thumb is that these concerns should be handled by an expert who knows how to tackle any issues that may arise. Investing in this particular aspect of your project can avoid major costs required to fix DIY mistakes or gaps. And we are talking about your home, where your family lives; another reason your investment is well spent.

What exactly is a contractor?

A contractor is an individual who helps you with either part of your new construction/remodeling project or who coordinates every aspect of your project. A contractor has knowledge of town permit requirements, available tradesmen for the particular jobs to be done, or may have his/her own skill set to accomplish your project.

As you approach your project in the planning stages, it’s a good idea to prepare a list including:

- Your project goals from top to bottom, ceiling to floor

- Your timeline, ideal start and finish dates

- Budget

- DIY items you would like to keep for yourself

Hiring a contractor for your kitchen project may save a significant amount of time and money in reaching your ultimate goal, leaving you to finish other projects in your home that are perfect for your level of DIY expertise.

If you plan to replace your floor, the time to prepare for it is BEFORE installing the cabinets and permanent appliances. Ceramic tile floors are usually placed before the installation of cabinets while vinyl flooring can be laid either before or after the cabinets are in place. If the new floor will go directly on top of the existing one, it is very important to fill any areas that may have dipped, buckled or bulged, as well as any holes or gouges, and nail down protruding boards. Remove glue or paint that may have spilled. Countersink nail and screw heads that are sticking up above the surface. If the old floor is embossed or has dips and/or hollows in it, these should be filled in with cement filler using a 5 to 10-inch wide putty knife.

If you plan to replace your floor, the time to prepare for it is BEFORE installing the cabinets and permanent appliances. Ceramic tile floors are usually placed before the installation of cabinets while vinyl flooring can be laid either before or after the cabinets are in place. If the new floor will go directly on top of the existing one, it is very important to fill any areas that may have dipped, buckled or bulged, as well as any holes or gouges, and nail down protruding boards. Remove glue or paint that may have spilled. Countersink nail and screw heads that are sticking up above the surface. If the old floor is embossed or has dips and/or hollows in it, these should be filled in with cement filler using a 5 to 10-inch wide putty knife. Most ready-made cabinets come with a scribe allowance at the edges to allow you to adapt them to irregular walls. Scribing simply involves running a strip of masking tape along the side to be scribed; then, positioning the cabinet. (See Fig. J) Set the points of a pencil compass to the width of the widest gap between the side of the cabinet and the wall. Run the compass down the wall and the irregularities will be pencil marked on the tape. Now you can plane or sand down to the line so the cabinet will rest flush against the wall. If the scribe edge is not included on your cabinets or if your cabinets go all the way to the ceiling, plan on trimming the edges with a small piece of molding.

Most ready-made cabinets come with a scribe allowance at the edges to allow you to adapt them to irregular walls. Scribing simply involves running a strip of masking tape along the side to be scribed; then, positioning the cabinet. (See Fig. J) Set the points of a pencil compass to the width of the widest gap between the side of the cabinet and the wall. Run the compass down the wall and the irregularities will be pencil marked on the tape. Now you can plane or sand down to the line so the cabinet will rest flush against the wall. If the scribe edge is not included on your cabinets or if your cabinets go all the way to the ceiling, plan on trimming the edges with a small piece of molding. Before installing any of our new cabinets, remove all the drawers, doors and hardware and label them as to their original locations for quick reassembly. This will make the units much lighter and more manageable.

Before installing any of our new cabinets, remove all the drawers, doors and hardware and label them as to their original locations for quick reassembly. This will make the units much lighter and more manageable. When readying the cabinets for installation, we recommend you first prepare those cabinets that will house a hood/vent, ducts and plumbing: Place the cabinet upside down on the floor with the hood in position upside down on the (bottom of the) cabinet. Trace the outline of the vent hole onto the base of the cabinet. Drill a starter hole for your sabre saw, then, cut around the outline and remove the cutout, Next, make a paper template of the ceiling or wall where the cabinet will be placed that shows where the end of the duct will enter. Place the template into position on the cabinet top or back and outline the duct hole. Again, drill a starter hole and cut out the circle with your sabre saw. Mark the location of the Wall studs on each cabinet’s hanging cleats; then, drill pilot holes for screws at these points. Self-drilling bugle head screws can also be used. These require no pre-drilling, except when using at face frames. With the doors removed, lift the first cabinet into position onto the ledger board and the temporary jacks. Check to see that the cabinet is both level and plumb in position and, if needed, add shims at the back of the cabinet to bring it into a plumb position.

When readying the cabinets for installation, we recommend you first prepare those cabinets that will house a hood/vent, ducts and plumbing: Place the cabinet upside down on the floor with the hood in position upside down on the (bottom of the) cabinet. Trace the outline of the vent hole onto the base of the cabinet. Drill a starter hole for your sabre saw, then, cut around the outline and remove the cutout, Next, make a paper template of the ceiling or wall where the cabinet will be placed that shows where the end of the duct will enter. Place the template into position on the cabinet top or back and outline the duct hole. Again, drill a starter hole and cut out the circle with your sabre saw. Mark the location of the Wall studs on each cabinet’s hanging cleats; then, drill pilot holes for screws at these points. Self-drilling bugle head screws can also be used. These require no pre-drilling, except when using at face frames. With the doors removed, lift the first cabinet into position onto the ledger board and the temporary jacks. Check to see that the cabinet is both level and plumb in position and, if needed, add shims at the back of the cabinet to bring it into a plumb position. Screw the 2-1/2 inch No. 8 flathead wood screws through the cleat at the back of the cabinet and into the wall studs – two at the top and two at the bottom. Use longer screws if needed to assure at least 1 -1/4″ to 1-3/4″ penetration into the studs. Each unit should be attached to a minimum of two studs. If only one stud is located behind a unit, add a toggle bolt as an additional fastener.

Screw the 2-1/2 inch No. 8 flathead wood screws through the cleat at the back of the cabinet and into the wall studs – two at the top and two at the bottom. Use longer screws if needed to assure at least 1 -1/4″ to 1-3/4″ penetration into the studs. Each unit should be attached to a minimum of two studs. If only one stud is located behind a unit, add a toggle bolt as an additional fastener. If your lower cabinets have freestanding bases, set the bases in position and level them, shimming if necessary. Also, use a framing square to square them where your base cabinets meet in a comer. When placing shim material, place a block of wood between the shim and the hammer so as not to damage the flooring. Then anchor them to the floor and place the cabinet units on top of them. Those cabinets without freestanding bases must be leveled and anchored in position as a unit. As you set the base cabinets in place, measure and leave room for our appliances, adding a 1/4 inch for clearance – more if you will be adding end panels. Check the position of your base units against the line on the wall, making certain the tops are equally below the line by the thickness of your counter top.

If your lower cabinets have freestanding bases, set the bases in position and level them, shimming if necessary. Also, use a framing square to square them where your base cabinets meet in a comer. When placing shim material, place a block of wood between the shim and the hammer so as not to damage the flooring. Then anchor them to the floor and place the cabinet units on top of them. Those cabinets without freestanding bases must be leveled and anchored in position as a unit. As you set the base cabinets in place, measure and leave room for our appliances, adding a 1/4 inch for clearance – more if you will be adding end panels. Check the position of your base units against the line on the wall, making certain the tops are equally below the line by the thickness of your counter top. Attach the cabinet units together so that the faces are flush. Slide a level down the entire length of the cabinets, adding a shim where there is a gap or to bring it up to level. Place your level front to back on the top of the cabinet to check for plumb – a again shimming if necessary. Then, screw the entire length o cabinets into the wall with the 2 – inch screws through the top cleat and into the wall studs. often, due to some unevenness in the wall, there will be gaps between the back of the cabinet and the wall. To avoid pulling your cabinets out of kilter as you position them to the wall, shim the gaps at the fastening point (where the stud is located) before screwing the cabinet into place.

Attach the cabinet units together so that the faces are flush. Slide a level down the entire length of the cabinets, adding a shim where there is a gap or to bring it up to level. Place your level front to back on the top of the cabinet to check for plumb – a again shimming if necessary. Then, screw the entire length o cabinets into the wall with the 2 – inch screws through the top cleat and into the wall studs. often, due to some unevenness in the wall, there will be gaps between the back of the cabinet and the wall. To avoid pulling your cabinets out of kilter as you position them to the wall, shim the gaps at the fastening point (where the stud is located) before screwing the cabinet into place.